In a collaborative effort aimed at enhancing operational efficiency and sustainability in glass production, Arglass and Zippe have teamed up for the construction of Arglass’s second plant in Valdosta, USA. Scheduled for installation in December 2024 and set to be commissioned in the second quarter of 2025, this partnership is poised to revolutionize the glass industry with modern technology.

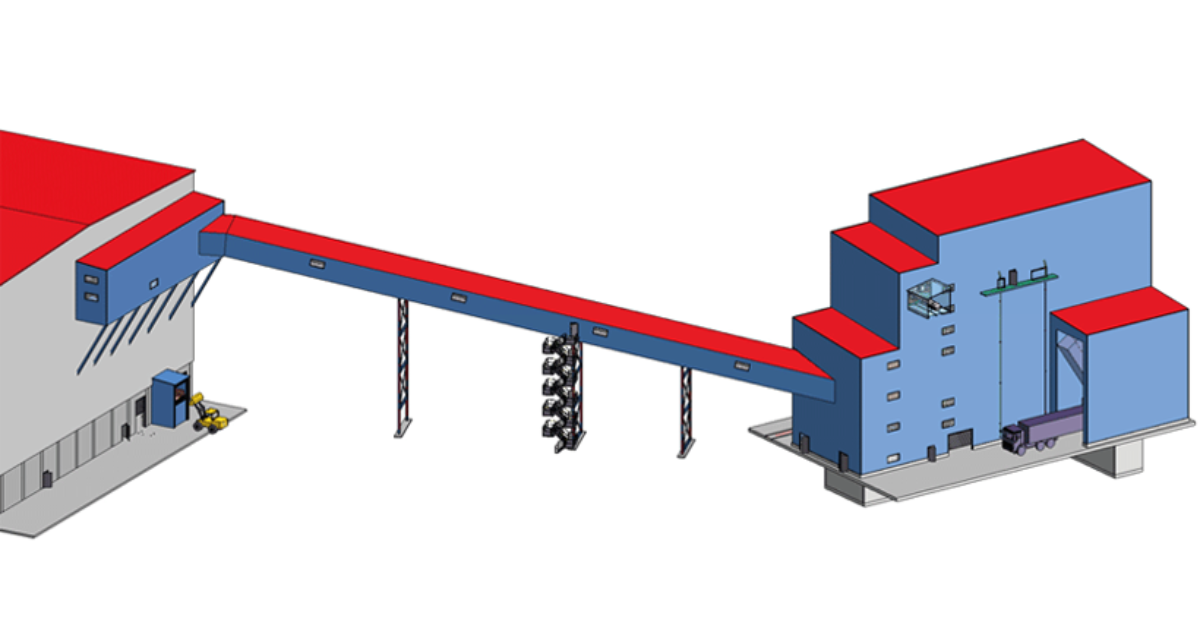

At the heart of this collaboration is Zippe’s state-of-the-art batch plant, designed specifically to meet the demands of modern glass production. With a daily capacity of 495 tons for the second furnace, this system is optimized for handling raw materials, pre-mixing, and batch transport processes.

The modular design of the batch plant ensures seamless integration into Arglass’s existing infrastructure, minimizing downtime during installation and commissioning phases. Key features of the batch plant include mechanical raw material feeding mechanisms like truck and train unloading systems equipped with vibratory tray feeders and elevators. The silo system can store up to 10 raw materials, with the largest silo having a volume of 500m3.

Arglass is also prioritizing sustainability by implementing a cullet return system that facilitates efficient recycling of glass cullet. This system includes scraping conveyors, crushers, falling tubes, and conveyor belts to support four IS machines. The integration of Zippe’s ZMART intelligent scraping conveyor control system will further optimize conveyor speed based on gob weight and quantity, reducing wear and energy consumption.

Overall, this collaboration between Arglass and Zippe promises to transform the way glass production is carried out through the use of cutting-edge technology that promotes efficiency and sustainability.

:quality(75)/cloudfront-us-east-1.images.arcpublishing.com/elcomercio/CSDWS3TIMBEWHCX7NFW3HIGKME.jpg)